How to address challenges in the end-to-end qualification of pluggable transceivers?

Despite the current COVID-19 pandemic, several market reports, including LightCounting’s Market Research of 2020, forecast strong global growth for optical transceivers, with an acceleration in the revenue growth higher than 20% in 2021. The demand for transceivers is booming and vendors need to produce and test thousands of 200G and 400G transceivers and active optical cables (AOC) each and every day. In parallel, transceivers based on photonic integrated circuits are expected to surge with several vendors having recently launched the first samples based on this promising technology bringing new benefits such as high compactness, reduced power consumption and better thermal management compared to traditional electronics circuits.

The main challenge right now is in speeding up manufacturing without any compromise in quality. This is why reliable and rapid end-to-end qualification matters. Before delving into testing considerations, let’s first have an overview of today’s optical transceivers.

Today’s optical transceivers at a glance

Optical transceivers come in a myriad of form factors and with different modulation formats, each adapted to the transmission rate and the network topology requirement. For instance, the highest rates (400G) are typically managed at the core and date centers, whereas the 5G fronthaul demands lower rates such as 25G and 50G. Regarding the coding modulation, NRZ is primarily used for optics between 1G and 100G, then PAM4 is the keystone technology to address optical components beyond 100G.

What to test?

During manufacturing, it is vital to ensure compliance with industry specifications and standards. Vendors should look for a simplified, comprehensive approach for quick and accurate validation. This implies electrical and optical tests, which are grouped under two categories:

- Die-level tests: parametric qualification of internal components performed during the design and production of the transceiver.

- Functional tests: mostly for quality control and performed once the transceiver is fabricated.

The importance of end-to-end transceiver qualification

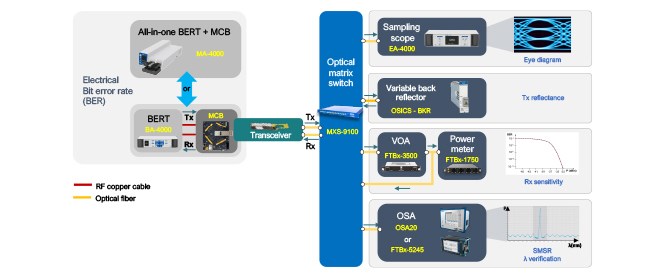

End-to-end transceiver qualification typically comprises a BER tester that is connected to the module compliance board (MCB) that hosts the transceiver sample. In the optical side of the transceiver, the signal is then sent through a switch to split the information for all the parametric tests, to the sampling scope for the analysis of the Eye diagram, to the variable back reflector to perform the transmitter reflectance testing, to the variable optical attenuator (VOA) cascaded with the power meter for the sensitivity receiver test, and to the optical spectrum analyzer for wavelength verification and side mode suppression ratio (SMSR) testing, respectively.

Best-in-class and complete solution to address transceiver qualification

End-to-end transceiver qualification requires an entire range of high-end optical and electrical testers. To help transceivers vendors ensure compliance throughout the transceiver lifecycle, EXFO has recently expanded its range of solutions for electrical and optical testing by acquiring InOpticals and its industry-leading electrical testers.

New to our portfolio:

- BA-4000: 400G/800G electrical bit-error-rate (BER) tester

- MA-4000: the most compact solution in the industry that combines a BER tester and a module compliance board (MCB)

- EA-4000: high-performance and ultra-fast electrical/optical sampling scope

These testers complement EXFO’s expertise in optical testing to provide extremely reliable and rapid transceiver qualification by leveraging best-in-class testing performances from end to end.

Interested in learning more on how to best design, test and validate the next generation of transceivers? Check out our flyer for more details into how our offering can help.