Data centers and the move to 400G

The need for more bandwidth is growing every day with 5G, IoT and video on demand fueling that growth. To support these technologies and applications, data centers are feeling pressure to upgrade their networks to 400G. Consequently, the move to 400G is a preoccupation for data center operators. Let’s take a look at what the migration to 400G means to data centers, from handling new transceivers to selecting 400G testers that can validate networks reliably and efficiently.

Increased traffic within and between data centers

Data centers are managing exponential increases in the volume of data moving through (i.e., intra-data center or IDC) as well as between (i.e., data center interconnection or DCI) their locations.

With hundreds of thousands of high-speed connections within a single data center, intra-data center upgrades to 400G are a formidable task. Plus, their scalable computing model means that data centers need to be architected with an understanding that additional 400G ports will be added much sooner than later.

New data centers are starting up every day as companies look to data centers to support load-balancing functions in day-to-day operations alongside the ‘traditional’ role of data centers as supporting business connectivity and disaster recovery. The uptick in the number of data centers includes installations popping up outside traditional urban centers. More data centers spread further apart is fueling the need for new technology that facilitates data center interconnectivity over increasingly longer distances. That’s where emerging technology such as coherent optics comes into play. Joining ZR optics that are already in use within the data center environment, coherent optics enable faster connections (as fast as 400G) across farther distances (beyond 120 km). I’ll get into more detail about coherent optics and coherent optical transceivers later in this blog.

With all these moving parts, staying agile is a prerequisite to success during this latest migration to ‘what’s next’—and this applies as much to data center infrastructure as it does to validation and qualification tools.

400G transceivers

Along with the migration to 400G—a move that’s well underway—the topic of transceivers is a hot one within the data center environment. In the race to higher speeds, pluggable optical transceivers play an enabling and predominant role. Pluggable optics featuring smaller form factors, lower power, lower cost and the ability to support more speeds are a driving force behind the ability to deliver 400G.

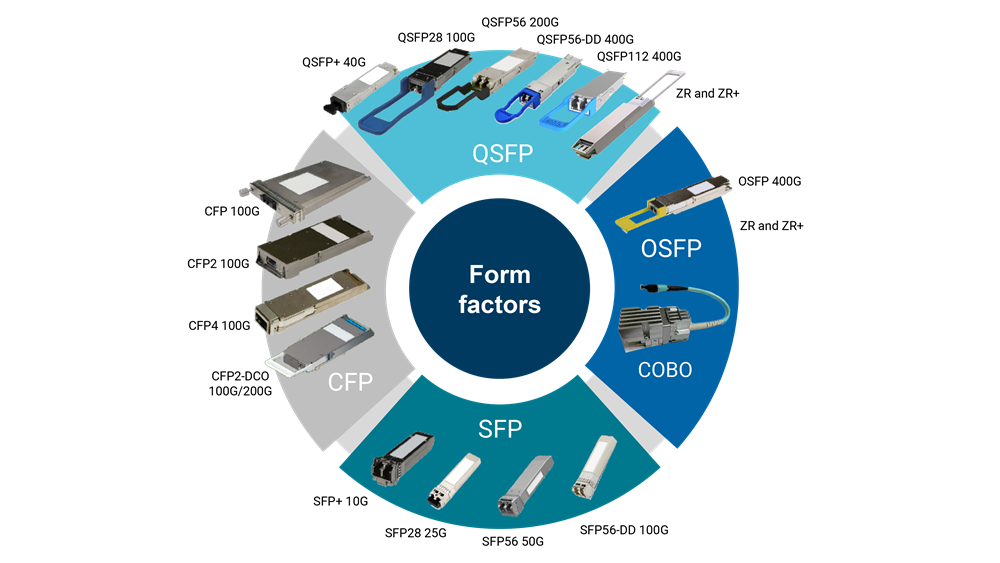

And then there’s the sheer volume of transceivers in the mix (see Figure 1). Even within each category of physical interface (e.g., QSFP-DD) there are different transceiver ‘flavors’ (e.g., long reach 10 km, coherent beyond 100 km) that support different rates (e.g., 25G, 40G, 100G, 400G etc.)—each one being a necessary component in the data-transmission puzzle. Managing and supporting all types and integrating them all within existing and next-gen infrastructure can be a juggling act.

Figure 1. Transceiver form factors.

New transceivers keep coming

Emerging new types of pluggable transceivers, managing huge quantities of transceivers, and their interoperability and integration within existing infrastructure are top of mind for data center operators. Integrating new types of physical interfaces (QSFP-DD, OSFP, SFPx) to support increasingly higher data rates constantly adds new complexity to data center operations. This constant push for lower power and smaller form factors means that new interfaces will keep coming. New types of transceivers include QSFP112. With 112G per lane, this is the future of transceiver technology and data centers will need to adapt to both implement and test these types of transceivers.

Importance of inspecting transceivers and cleaning fiber connectors

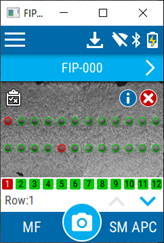

Making sure these multitudes of fibers and transceivers are in working shape is a daunting, albeit important task. Dirty connectors and problems with transceiver hardware are major problems faced by technicians within data centers. Too often, because they lack the proper test tools, technicians discard a presumably faulty transceiver. When thousands of pluggable transceivers are at play, this rip-and-replace strategy is costly as well as time consuming. Failure to flag dirty fibers connectors can lead to unnecessarily long network downtimes as well. Technicians waste time locating root causes (i.e., router, transceiver or switch) when the problem was an easy-to-clean fiber connector (Figure 2).

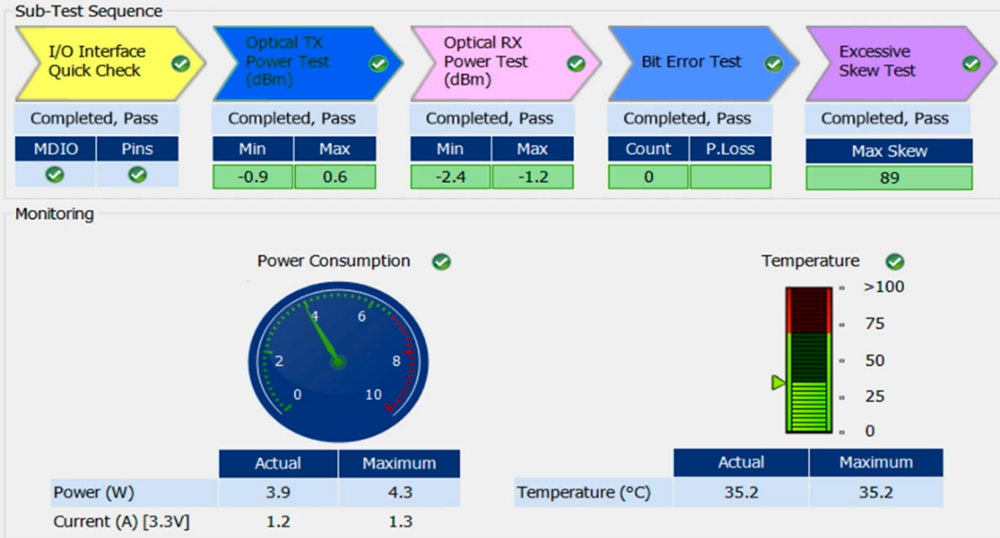

At 400G, inspecting and cleaning fibers is especially important. With high-speed rates, any problem on fibers or connectors can cause serious errors which can dramatically impact service performance. Having the right tools to check and clean connectors is very important. But the task does not end there, using automated tools to validate the performance on power, register memory and temperature of a transceiver are very important as well (Figure 3). This data provides the technician with a complete picture of the connection and reduces troubleshooting time.

Figure 2. Clean and dirty connectors (LC duplex and MPO), as seen through the eyes of EXFO’s FIP-500 fiber inspection scope.

Figure 3. Transceiver passing inspection performed by EXFO’s iOptics.

Coherent optics

As I discussed above, new transceivers continue to emerge taking on various formats and supporting higher data rates. This adds a new level of complexity as the ability to scale to ‘what’s next’ meets the need to manage ‘what’s now’. Coherent pluggable optics are one of the latest transceiver types to have arrived on the scene (see Figure 2).

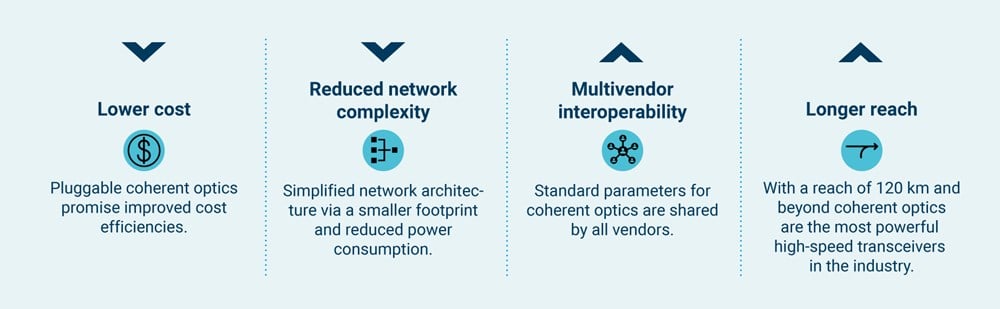

Coherent light comes to the rescue! Promising a reduced cost per bit, simplified architecture (IP over DWDM), longer transmission capacity and the ability to interop with existing routers and switches, these new optics are critical to successfully broadening the support of 400G hardware across DCIs and metro networks (Figure 4). Coherent optics (e.g. ZR, ZR+ etc.) are a favorite of data centers as they facilitate long-distance interconnections—as far as 120 km and beyond—between data centers.

Figure 4. Benefits of coherent pluggable optics.

Validating AOC and DAC cables

Active optical cables (AOCs) and direct attach cables (DACs) are the dominant cabling technologies used for high-speed links within the server racks―and given their many potential advantages they are being widely deployed in high-performance computing and data center applications. AOC assemblies were developed to replace copper technology and can provide a cost-effective means to connect top-of-rack (TOR) switches to spine aggregation switches for speeds all the way up to 400G (and beyond). Without the right testing measures in place (i.e., ability to test power consumption and optical power levels, determining cable temperature etc), validating cables can become a huge challenge for data center managers.

Testing 400G in the data center

Given this migration to 400G, and all that this upgrade requires, data centers need to be equipped with test solutions that enable them to reliably test and validate as many 400G links as possible in the shortest amount of time. With the FTBx-88480, EXFO’s dual-port 400G test solution, data center operators can validate two circuits simultaneously for speeds up to 400G with a single test solution. Built with 112G electrical lanes, this solution can test today’s transceivers while staying ready for tomorrow’s next-gen technologies. EXFO’s unique onboard Open Transceiver System (OTS) features swappable transceiver testing modules so data center technicians can test multiple types of transceivers and rates simply by swapping out OTS modules directly on the data center floor. The OTS’ future-proof design also means that as new transceivers emerge, new OTS modules become available—saving CAPEX and being friendlier on the environment by eliminating the necessity to replace an entire testing solution. On the fiber side, EXFO’s FIP-500 delivers simple-to-use fiber inspection in the form of a 100% automated fiber inspection scope. And the iOptics automated, intelligent test application provides an accurate, efficient way to test for faulty transceivers as well as faulty AOC and DAC cables.